(First published in The Sunday Telegraph)

The origin of the term “bodging” is the old custom of sealing the headlaps of roof tiles by trowelling on lime-and-horsehair mortar from the inside. This traditional practice stopped rain or snow being blown in, whilst still allowing the roof to “breathe”.

It is obvious how, from such noble beginnings, the word “bodge” later came to refer to a clumsy bit of plastering or other repair work, and thence to its modern use for any kind of bad work. It is also ironic that one of the biggest bodges around now is the sealing of roofs against the elements from the inside – only the modern bodging, rather than using dollops of lime and horsehair, is to spray the whole roof with foam.

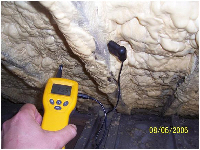

I wrote about this practice a few months ago, pointing out that spraying foam onto the undersides of slate or tile roofs is actually a bad idea. It is advertised as a cheap alternative to a proper roofing overhaul, but is very much a short-term solution; the foam makes it difficult for the slates or tiles to ever be re-used, and increases the likelihood of condensation in the rafters and battens, hence hastening the process of wood rot.

The National Federation of Roofing Contractors, which represents the responsible end of the roofing industry, even publishes a Technical Bulletin on the subject, which points out the risks that foam under-coatings pose to roof timbers. The Bulletin advises that the foam should not make contact with any of the timbers, which – since the process involves spraying foam over the battens – is clearly not possible. A spokesman for the NFRC told me that the only situation where he could recommend a foam under-coating would be to extend the life of an old dilapidated building, such as a farmer’s barn, for another few years until it was demolished. He said the system was unsuitable for domestic properties, as it interferes with the two essential principles of good roofing practice – that a roof should be able to move, and that it should be able to breathe.

The foam under-coating industry has naturally been very upset by my comments, and insists there have been no reported cases of condensation or wood rot. This is hardly surprising, as even if any of the industry’s clients were in the habit of climbing ladders and crawling around on their roofs to check for problems, they would be unable to see much – the foam stops tiles being lifted from the outside, and the battens are hidden by foam on the inside. The condensation and rot are taking place out of sight and out of mind.

Apart from denying the existence of any problems, the foam sprayers are also not above making fanciful claims for their product. One firm was recently pulled up by the Advertising Standards Authority for falsely claiming that the process was “Government approved”, and “Recommended by Chartered Architects and Surveyors”. Adverts for foam under-coatings also regularly claim compliance with the Building Regulations, which is difficult to comprehend – my copy of the Building Regs makes it clear that where insulation follows the pitch of a roof, there should always be a clear ventilated 50 mm air gap between the insulation and the roof covering.

So if you are thinking of having your roof under-coated, then think again. And if you have already had it done, and feel that the product has been mis-sold to you, then you may wish to discuss it with your local authority Trading Standards Office.